- nach Hause

- >

- Produkte

- >

- Tungsten Carbide Drawing Dies

- >

- China manufactrer of tungsten carbide punch carbide wire drawing dies

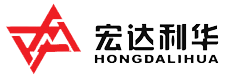

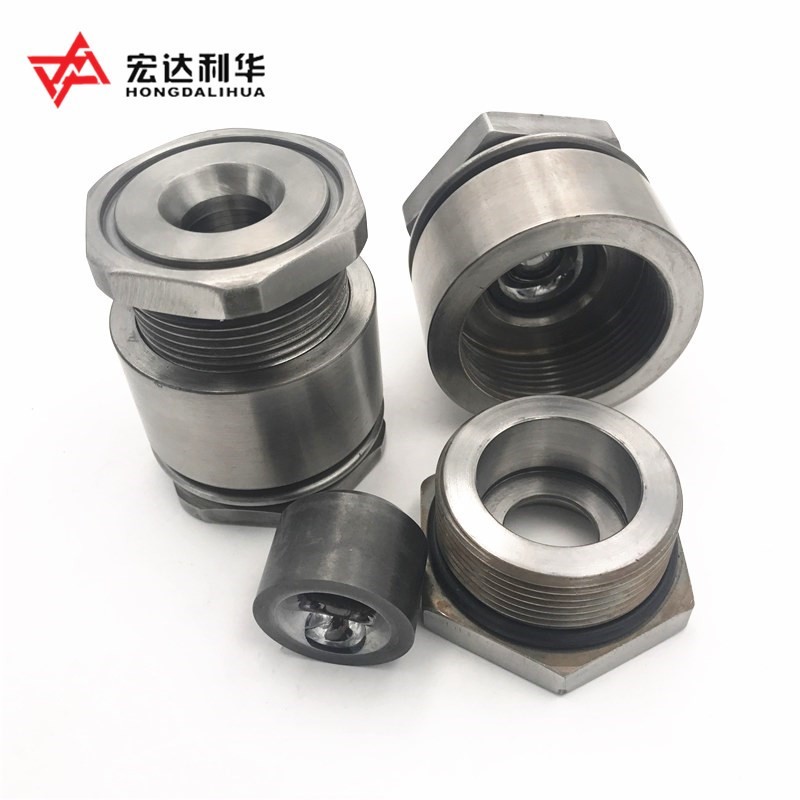

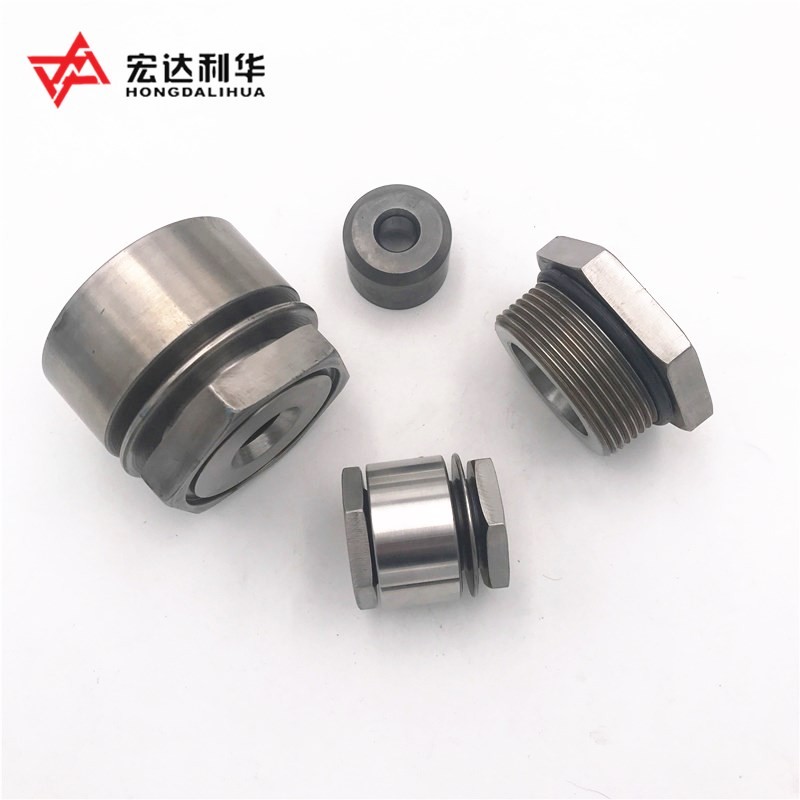

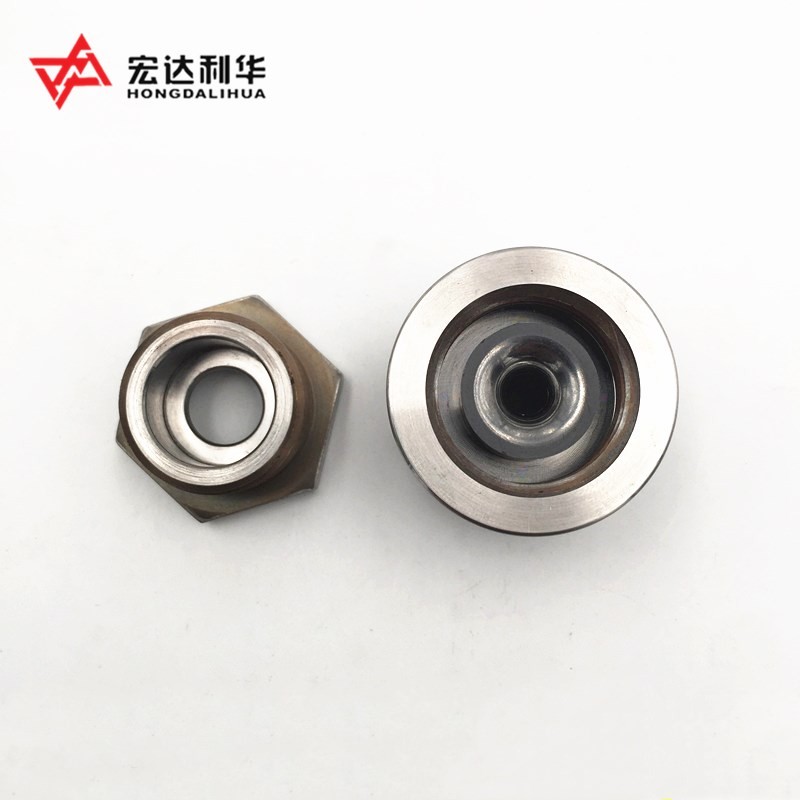

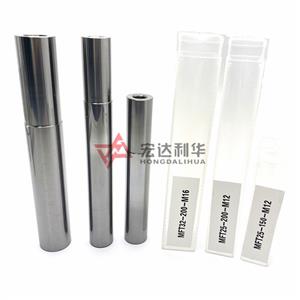

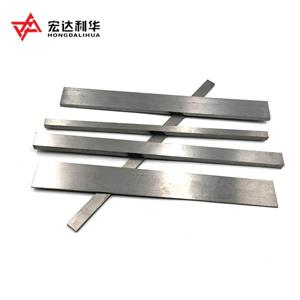

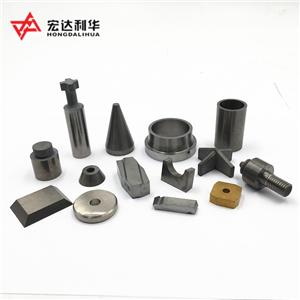

China manufactrer of tungsten carbide punch carbide wire drawing dies

marke :Lihua

Die HERKUNFT der Produkte :Zhuzhou, China

Die lieferzeit :7-15 Working Days

Die fähigkeit, :50000 Prices per Month

China Manufactrer of Tungsten Carbide Punch Carbide Wire Drawing Dies

Applications

We Die's wire drawing system is used by wire producers to reduce a cross-section of wire by pulling the wire through a single die or a series of drawing dies. There are many applications for wire drawing, including electrical wiring, construction reinforcement, cables, medical and surgical applications, springs, staples, tire cord,and welding wire.

Welding Wire

Enough welding wire is produced every year to circle the globe several times. Hundreds of thousands of wire drawing dies are consumed during the production of welding wire.

Tire Cord

There are more than 1 billion tires produced every year and each tire contains bands of high tensile-strength steel wire encased in a rubber compound. Millions of wire dies are consumed each year in the production of tire cord wire.

Spring Wire

Millions of heavy duty and light vehicle engine valve, piston, fuel injection, transmission, and clutch springs are produced each year. Hundreds of thousands of wire drawing dies are consumed annually during the production of spring wire.

PC Strand

PC strand is primarily used in pre-stressed concrete buildings, bridges, parking decks, and other structures. High carbon steel rod is drawn through carbide wire dies before being used as concrete reinforcement.

Fasteners

All over the world millions of screws, bolts, nuts, rivets, nails, and staples are produced each year. Carbide wire drawing dies are essential to the production of these fasteners.

Wire Rope / Cable

Wire rope and cable are used in many industries - spanning aerospace and construction to medical and transportation. Wire drawing dies are used to form the control, constraint, and security cables used in these industries.

Specifications

No | Product | Items | Mold Core | Hardness |

1 | Wire-drawing Die | W103 | φ13*10 | 1400-1600 |

1600-1800 | ||||

2 | Wire-drawing Die | W104 | φ16*13 | 1400-1600 |

1600-1800 | ||||

3 | Wire-drawing Die | W105 | φ20*17 | 1400-1600 |

1600-1800 | ||||

4 | Wire-drawing Die | W106 | φ25*18 | 1400-1600 |

1600*1800 | ||||

5 | Wire-drawing Die | W107 | φ30*22 | 1400-1600 |

1600-1800 | ||||

6 | Wire-drawing Die | W108 | φ35*25 | 1400-1600 |

1600-1800 |

Items | Mold Core | Mantle | Coating Film | Specification | Tolerance | Compression Corner | Coining |

W109 | 40*27 | 53(-0.1~-0.2)*34 | AlCrN | 13.30 | 0-0.01 | 14 | 25% |

13.10 | |||||||

W108 | 35*25 | 12.80 | |||||

12.70 | |||||||

12.40 | |||||||

12.10 | |||||||

11.70 | |||||||

11.40 | |||||||

11.10 | |||||||

10.70 | |||||||

10.60 | |||||||

10.10 | |||||||

W107 | 30*22 | 9.90 | |||||

9.60 | |||||||

9.10 | |||||||

8.90 | |||||||

8.10 | |||||||

W106 | 25*18 | 7.10 | |||||

6.10 | |||||||

W105 | 20*11 | 5.10 | 30% | ||||

4.90 | |||||||

4.10 | |||||||

W104 | 15*10 | 3.80 | |||||

3.50 | |||||||

3.30 | |||||||

3.20 | |||||||

3.10 | |||||||

3.00 |

Tungsten Carbide Punch Carbide Wire Drawing Dies