- nach Hause

- >

- Nachrichten

- >

- Industry News

- >

- On cemented carbide and its application

On cemented carbide and its application

On cemented carbide and its application

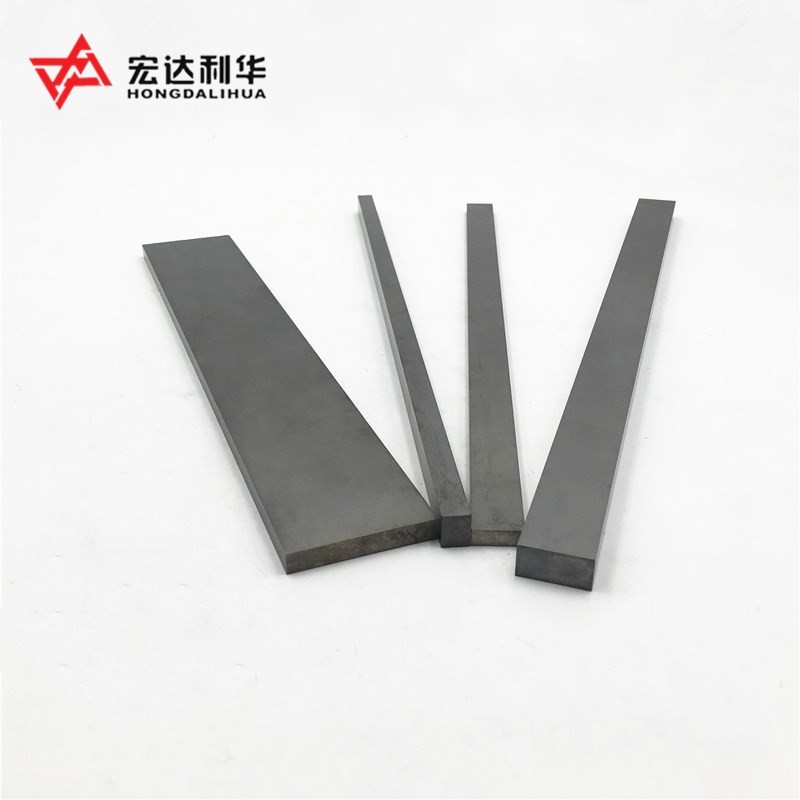

1. Cemented carbide and its characteristics

The term "hard alloy" generally refers to a kind of alloy composed of refractory hard metal compounds and bonded metals, which is produced by the processes of powder making, molding and sintering. Refractory metal compounds commonly used are tungsten carbide (WC), titanium carbide (TiC), tantalum carbide (TaC) and so on. The bonding metals are mainly cobalt, as well as nickel and a small amount of other metals.

Cemented carbide is composed of refractory metal hard compound and binding metal composite materials, refractory metal carbides, often referred to as the periodic table the first Ⅳ, Ⅴ, Ⅵ of tungsten, titanium, tantalum, vanadium, elements of hafnium carbide, in cemented carbide is one of the most widely used in doing the WC, TiC, TaC, one or more than one of these carbide and binder of drill is often called the carbide alloy, these alloys generally have high hardness, good wear resistance, good red hardness and chemical with high thermal stability, high compressive strength and corrosion resistance, etc.

2. Use of cemented carbide

Cemented carbide has a series of excellent properties, the use is very broad, with the passage of time the use is still expanding, the main USES are described as follows:

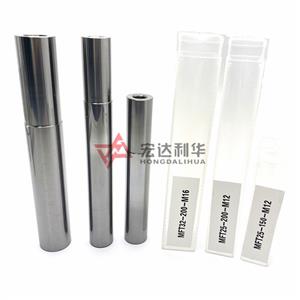

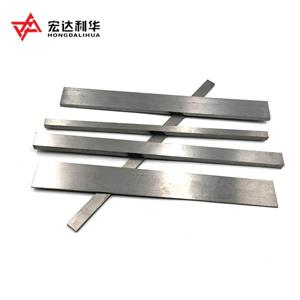

(1) cutting tools: cemented carbide can be used as a variety of cutting tools. In China, the amount of cemented carbide used for cutting tools accounts for about one third of the total output of cemented carbide, of which about 78% is used for welding tools and 22% is used for indexable tools. And nc tool with cemented carbide tool with only about 20% of the indexable tool with cemented carbide, in addition to the whole cemented carbide bit, the whole cemented carbide small circular saw blade, cemented carbide micro drill and other cutting tools.

(2) geological mining tools: geological mining tools are also a major use of cemented carbide. In China, the cemented carbide used in ground mines accounts for about 25% of the total production of cemented carbide, which is mainly used for rock percussion drill, drill bit for geological exploration, DTH drill for mining and oil field, cone drill, cutter cutter and impact drill for building materials industry.

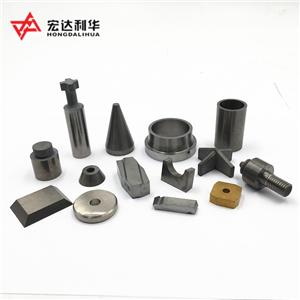

(3) the mold: used for all kinds of mold of the carbide accounted for about 8% of the total hard alloy production, drawing die, cold heading die, cold extrusion molding, hot extrusion die forming dies, hot forging die, as well as drawing tube core rod, such as the long core rod, ball core rod, a floating core rod, etc., in recent years rolled wire with all kinds of cemented carbide roll consumption growth quickly, roll used cemented carbide in China has accounted for 3% of total cemented carbide production.

(4) structural parts: cemented carbide used for structural parts of many products, such as rotary seal ring, compressor piston, lathe chuck, grinding machine spindle, bearing journal.

(5) wear-resisting parts: the wear-resisting parts made of hard alloy include nozzle, guide rail, plunger, ball, tire anti-skid nail, snowplow board and so on.

(6) high pressure and high temperature resistant cavities: the most important use is to produce products such as anvil and cylinder for synthetic diamond. The cemented carbide used for anvil and cylinder has accounted for 9% of the total production of cemented carbide in China.

(7) other USES: cemented carbide is more and more widely used, and has been expanded in the civil field in recent years, such as watch chain, watch case, zipper head of high-grade cases and bags, cemented carbide trademark.

3. Classification of cemented carbide

(1) tungsten-carbide base cemented carbide: including WC -- Co, WC -- TaC -- Co, WC -- TiC -- Co, WC -- TiC -- TaC -- Co, WC -- Ti -- TaC -- NbC -- Co and other alloys, these alloys are mainly composed of tungsten carbide.

(2) titanium carbide or titanium carbonitride carbide: usually TiC or Ti (C, N) as the basic component, with ni-mo as the binder and composed of a hard alloy. In recent years, there have been many new developments in this kind of cemented carbides, such as the addition of multi-compound carbide solid solution containing Ta, W and other heavy metal elements to the development of high-performance Ti (C, N) based cermet.

(3) chromium carbide base cemented carbide: based on Cr3C2, with Ni or Ni -- W as binder and composed of hard alloy, usually used for wear and corrosion resistant parts, in recent years is also widely used in decorative parts such as watch chain.

(4) steel-bonded hard alloy: it is a kind of hard alloy with TiC or WC as the base and steel as the binder. It is an alloy that can be machined and heat treated. It is an engineering material between traditional hard alloy and alloy steel.

(5) coated carbide: usually refers to the toughness of tungsten carbide-based carbide matrix by chemical vapor deposition or physical coating method, coated with a few microns thick TiC, TiN, Ti (C, N), Al2O3 and other hard compounds produced.

4. History of cemented carbide development

In 1923, the German schleter invented cemented carbide

In 1926, German krupp company began industrial production of cemented carbide (tungsten cobalt)

In 1929, krupp began to produce tungsten, cobalt and titanium cemented carbides

In 1965, krupp developed coated cemented carbide

Since 1970, superfine cemented carbide, hot isostatic pressure, spray drying, surface treatment, addition of rare earth, etc

Double high alloy (sumitomo electric co., LTD., Japan)

Low pressure thermal isostatic equipment (uhv), 1989

Since 1990, ultra-fine, ultra-coarse, coating, gradient alloy, heat treatment, surface treatment has become a development trend.